RESISTANCE WELDING SOLUTIONS

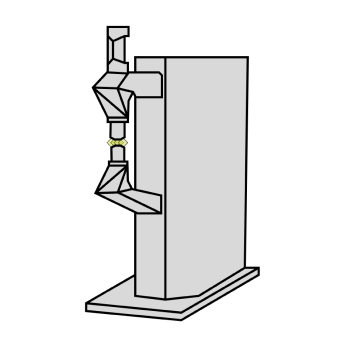

S3FDC-130

3 Phase DC Spot/ Projection Welding Machine

S3FDC-130

3 Phase DC Spot/ Projection Welding Machine

SD4B/E

Transverse/Longitudinal Seam Welding Machine

SD4B/E

Transverse/Longitudinal Seam Welding Machine

2-SDGK-2×270

Fully Automatic Wavewall Mig Welding Machine

2-SDGK-2×270

Fully Automatic Wavewall Mig Welding Machine

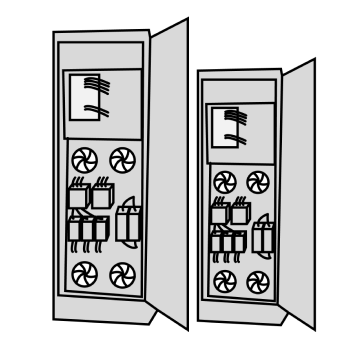

SPR54-125

MFDC Spot Projection Welding Machine

SPR54-125

MFDC Spot Projection Welding Machine

SP-11

Desktop Double Head Resistance Wire Welding Machine

SP-11

Desktop Double Head Resistance Wire Welding Machine

SP-11-1

Two Head Resistance Wire Servo Spot Welding Machine

SP-11-1

Two Head Resistance Wire Servo Spot Welding Machine

SP4-2H

Double Spot Welding Machine with Hydraulic Balance

SP4-2H

Double Spot Welding Machine with Hydraulic Balance

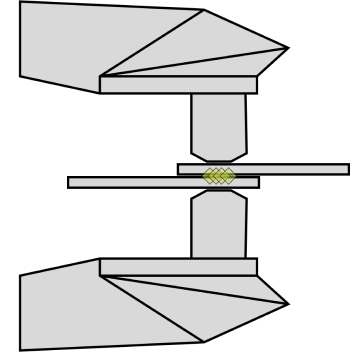

SPR4 x2

Bottom-Top Cylinder Projection Welding Machine

SPR4 x2

Bottom-Top Cylinder Projection Welding Machine

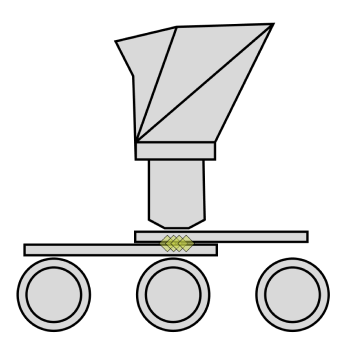

C-MOTION 2

Two Station C-Motion Spot Welding Machine

C-MOTION 2

Two Station C-Motion Spot Welding Machine

TKKM4/120

Automatic Wire Condenser Multi Spot Welding Machine

TKKM4/120

Automatic Wire Condenser Multi Spot Welding Machine

SP24x2-30-545

Automatic Feeding Spot Welding Machine

SP24x2-30-545

Automatic Feeding Spot Welding Machine

SKPK-311

Automatic Starter Collector Spot Welding Machine

SKPK-311

Automatic Starter Collector Spot Welding Machine

SKKM16-SKKM24

Semi-Automatic Sheet Metal Condenser Welding Machine

SKKM16-SKKM24

Semi-Automatic Sheet Metal Condenser Welding Machine

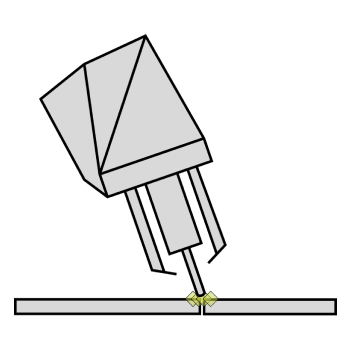

SJKB-1-345

Wheel Cover Retaining Pin Projection Welding Machine

SJKB-1-345

Wheel Cover Retaining Pin Projection Welding Machine

SHD–330

Quick Change Wire Mesh Welding Machine

SHD–330

Quick Change Wire Mesh Welding Machine

S-VBB-SK-347

Exhaust Emission Tank Automatic Projection Welding Machine

S-VBB-SK-347

Exhaust Emission Tank Automatic Projection Welding Machine

S-ODT-364

Automatic Rotary Table Multi Spot Welding Machine

S-ODT-364

Automatic Rotary Table Multi Spot Welding Machine

S-DDP-2×70-360

Wave Wall Double Spot Welding Machine

S-DDP-2×70-360

Wave Wall Double Spot Welding Machine

S-CNC-356.02

Automatic Feeding Projection Welding Machine with Moving Table

S-CNC-356.02

Automatic Feeding Projection Welding Machine with Moving Table

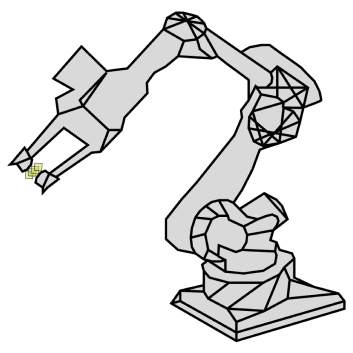

CNC4-X1-MF

Simotion C 4 Axis 3 Head Spot Welding Machine

CNC4-X1-MF

Simotion C 4 Axis 3 Head Spot Welding Machine

CNC-X4-120

Cnc 4 Station Spot Welding Machine

CNC-X4-120

Cnc 4 Station Spot Welding Machine

C-DT-NC-355

Special Nc Welding Machine with Rotary Table

C-DT-NC-355

Special Nc Welding Machine with Rotary Table

SCP-X10-339

Exhaust Multi Spot Welding Machine

SCP-X10-339

Exhaust Multi Spot Welding Machine

WHAT ARE RESISTANCE WELDING SOLUTIONS?

Resistance welding – also known as electrical resistance welding (ERW) – is simply a method of joining two metal parts by interlocking at the point where the current and force are applied, by applying the required force and strong electric current.

Although it has different forms and applications such as spot welding, projection welding, seam welding, butt welding, this method does not require any additional material, which makes it a very efficient process.

Advantages

It is an efficient and low cost joining method.

It is open to a wide range of automation applications and development.

It is an environmentally friendly and healthy method due to its very low smoke emission.

Process times are very short.

No additional bonding material, filler wire or chemicals are needed.

CATEGORIES